Getting Started with a 20W Fiber Laser: Basic Engraving Settings for Stone, Aluminum, Steel, Stainless, and More

If you’ve just picked up a 20W fiber laser and you’re wondering what settings to use — welcome to the club. Every engraver goes through that “trial and error” phase where you’re juggling speed, power, and frequency to get the perfect mark. The good news? Once you understand the basics, you’ll start dialing in great results much faster.

Let’s break down some starting points and what each material typically needs. (Just remember: every laser and lens setup is a little different, so always test before engraving your final piece!)

🪨 Stone

Stone isn’t technically what fiber lasers are built for — they’re made for metal. But with enough power and patience, you can get light markings on certain stones.

-

Power: 90–100%

-

Speed: 300–1000 mm/s

-

Frequency: 30–60 kHz

The results are usually a white or light gray mark. Go slow and repeat passes if needed. It’s more about surface chipping than deep engraving here.

🪙 Aluminum

Aluminum is one of the easiest metals to engrave with a 20W fiber laser.

-

Power: 70–90%

-

Speed: 800–1500 mm/s

-

Frequency: 30–50 kHz

This combo gives crisp, bright marks. Lower the power slightly if you start seeing melted edges or color distortion.

🧲 Steel (Carbon or Mild Steel)

Steel loves fiber lasers, but it can heat fast, so moderation helps.

-

Power: 60–85%

-

Speed: 700–1200 mm/s

-

Frequency: 30–60 kHz

A slower speed will deepen the mark, while higher frequency helps smooth it out. If you’re aiming for color annealing, you’ll need even slower speeds and lower power.

🪵 Stainless Steel

Stainless is similar to mild steel but can reflect more light, so don’t go too fast.

-

Power: 70–95%

-

Speed: 600–1000 mm/s

-

Frequency: 25–40 kHz

For dark or black marks, drop the speed to around 400 mm/s and increase your line spacing density — that’s what helps heat the metal evenly for deeper oxidation.

🟡 Brass

Brass can be tricky because it reflects light like crazy and conducts heat quickly.

-

Power: 80–100%

-

Speed: 800–1500 mm/s

-

Frequency: 20–40 kHz

The key is to avoid burning or melting. Use multiple light passes instead of one strong one. Keep your focus sharp — brass engraving rewards precision.

⚙️ Pro Tips

-

Always clean your material before engraving; oils and coatings can mess with the laser’s reflection.

-

Make sure your focus height is perfect — even a millimeter off can blur your design.

-

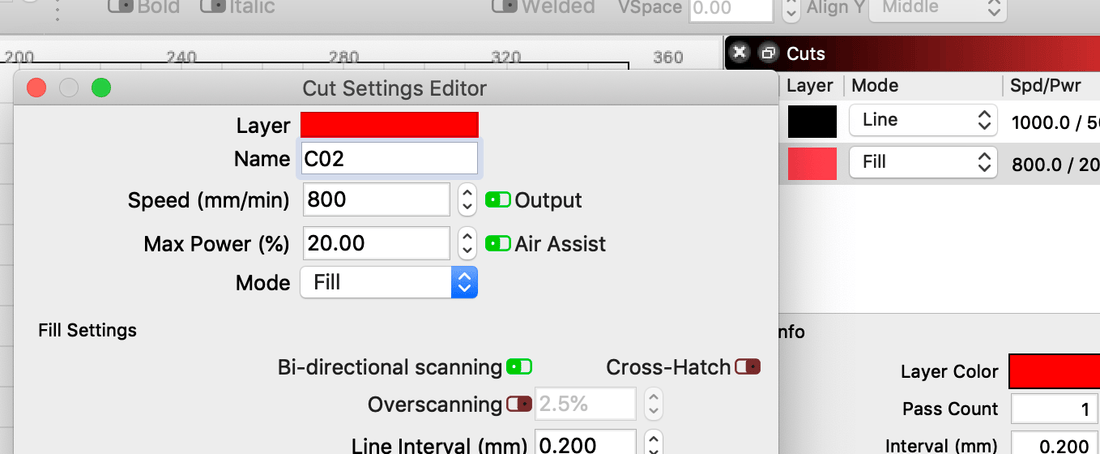

For best contrast, adjust line spacing (interval) between 0.03–0.05 mm.

-

Frame before you fire — trust me, it saves projects (and sanity).

A 20W fiber laser may not be the most powerful option on the market, but it’s a workhorse. With the right settings, it can engrave everything from jewelry and dog tags to tools, trophies, and even small stones. Once you get your sweet spots for each material, you’ll find your rhythm — and you’ll wonder how you ever worked without it.